Promoții

Descoperă produsele și soluțiile Häfele disponibile la prețuri promoționale.

Aţi fost deconectat din motive de securitate.

Găsiți produse fie prin scanarea codului QR, fie a codului EAN

Imposibil de detectat / cod invalid

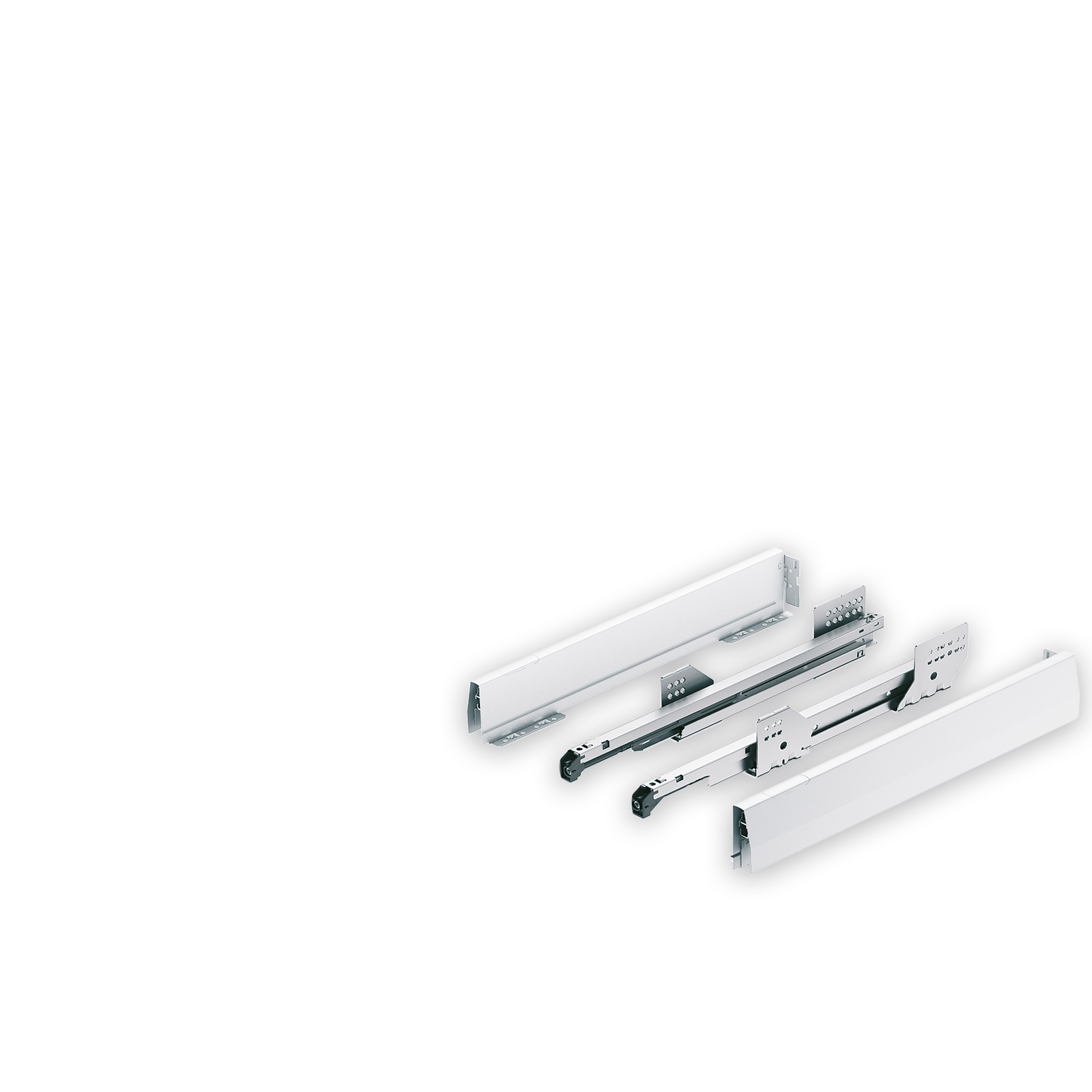

Achiziționează glisiere sub sertar Matrix UM A25 sau Matrix UM A30 Synchro și pentru fiecare 10 seturi comandate, Häfele îți oferă 2 seturi gratuite.

Vezi campaniaIntegrează mecanismul pentru uși glisante pivotante Häfele Slido F-Park71 16A în proiectele tale și beneficiezi de 25% discount.

Vezi campaniaDescoperiți noua ediție a celui mai apreciat catalog de feronerie din România.

Deschideți catalogDescoperiți gama de mecanisme de ridicare pentru uşi de mobilier.

Aflați mai multeIndiferent dacă este vorba de studenţi, absolvenţi sau specialişti, Häfele caută în toată lumea colaboratori calificaţi. Informaţi-vă asupra posturilor libere, trimiteţi o candidatură online şi deveniţi parte a lumii Häfele.

La secţiunea comunicatelor de presă găsiţi cele mai proaspete informaţii, persoana de contact potrivită pentru verificarea ştirilor şi o perspectivă generală asupra activităţilor companiei.

Häfele este o companie multinaţională care îşi desfăşoară activitatea în domeniul producţiei şi comercializării de accesorii şi feronerie pentru mobilier sau proiecte arhitecturale şi al sistemelor electronice de control al accesului. În întreaga lume, clienţii din industria mobilei, comercianţii şi producătorii de mobilier, dar şi arhitecţii, designerii şi beneficiarii din domeniul construcţiilor mizează pe competenţa şi performanţele companiei Häfele.